The 3D Design service of Outdoor Portable Power Station

From Concept to Validation: The Integrated Design of Outdoor Portable Power Station

The market for portable power stations is fiercely competitive, demanding products that are not only highly functional and safe but also aesthetically compelling. This case study chronicles the design journey of the "Atlas," a 1000Wh outdoor power station, with a specific focus on its enclosure. We will trace its evolution through three critical phases—Product Sketching, Appearance Design, and Structural Design—with a particular emphasis on how the creation of physical prototypes at each stage was instrumental in de-risking the development and ensuring a superior final product.

Phase 1: Product Sketching – Tangible Ideation

The process began not on a computer, but on paper. The design team's goal was to conceptualize a product that embodied "rugged reliability." Dozens of freehand sketches explored themes from geological forms to modern architectural elements.

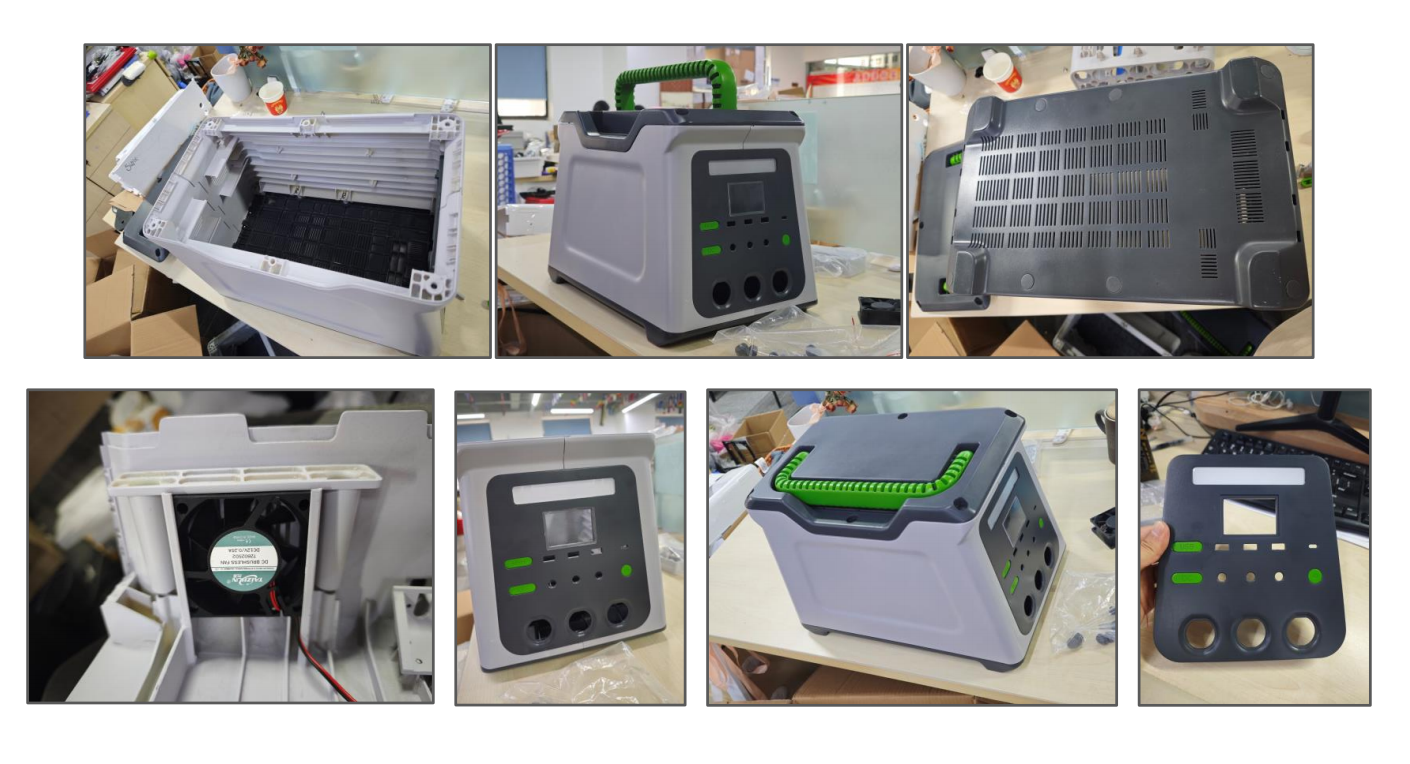

Early sketches focused on core user interactions: the grip of the handle, the angle of the control panel, and the overall silhouette. However, a key challenge emerged from these 2D explorations: how would a user intuitively lift a 20kg unit? To answer this, the team quickly moved to create rough, non-functional "looks-like" models, often 3D printed in multiple parts or hand-sculpted from foam.

*A designer holds a coarse, white 3D-printed model of a early concept, assessing the handle's ergonomics and the unit's center of gravity.

These initial physical models were invaluable. They revealed that a centrally located handle, while visually balanced, made the unit feel unstable and awkward to carry. This hands-on feedback led to a pivotal design change: the handle was shifted slightly forward, creating a natural pivot point that made the heavy unit feel significantly lighter and more manageable. This early prototyping step grounded the creative vision in physical reality, preventing a major ergonomic flaw from progressing further.

Phase 2: Appearance Design– Validating Form and Feel

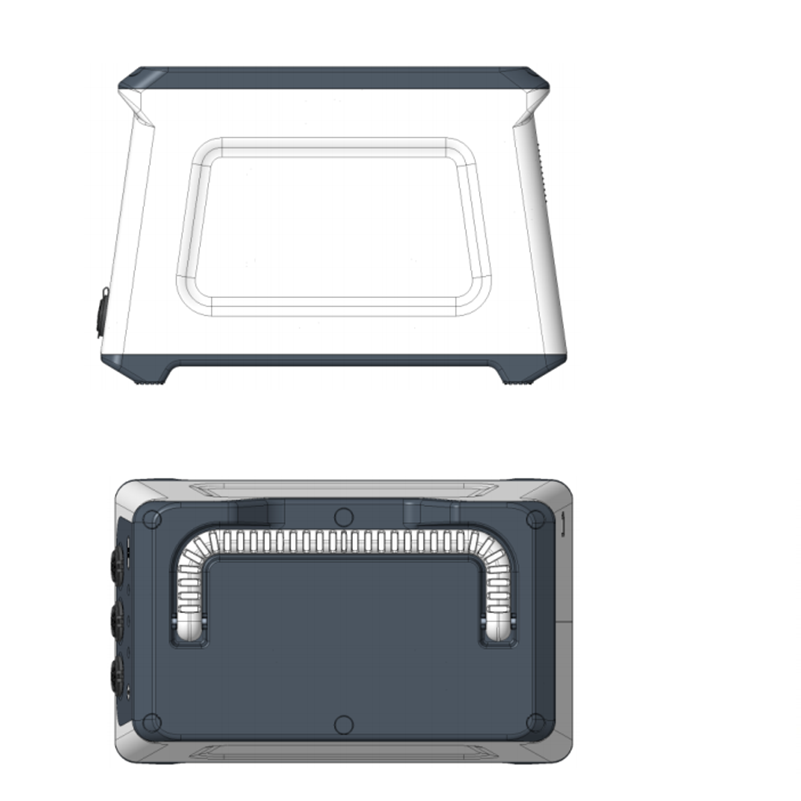

With a validated ergonomic concept, the project advanced to the digital sculpting phase. Using CAD software, designers refined the surfaces, ensuring perfect continuity and a premium feel. The chosen design language combined a monolithic, protective shell with strategic accents.

The CMF (Color, Material, Finish) strategy called for a two-tone design: a textured, dark gray polycarbonate body for durability, contrasted with matte orange aluminum panels for heat dissipation and high visibility in outdoor settings. To validate these choices, high-resolution "design validation models" were produced using multi-jet fusion and urethane casting.

An industrial designer places a full-color, high-fidelity prototype on a table next to camping gear, evaluating its visual appeal and brand presence in a realistic context.

These models, which accurately replicated the intended colors and textures, were crucial for stakeholder reviews and user focus groups. They allowed the team to confirm that the orange accent was not too loud, the texture provided adequate grip, and the overall product looked at home alongside high-end outdoor equipment. This phase transformed the product from a promising digital model into a tangible object that could be emotionally evaluated, leading to subtle but important refinements in surface gloss and graphic placement before committing to expensive production tools.

Phase 3: Structural Design – Engineering Proof through Functional Prototyping

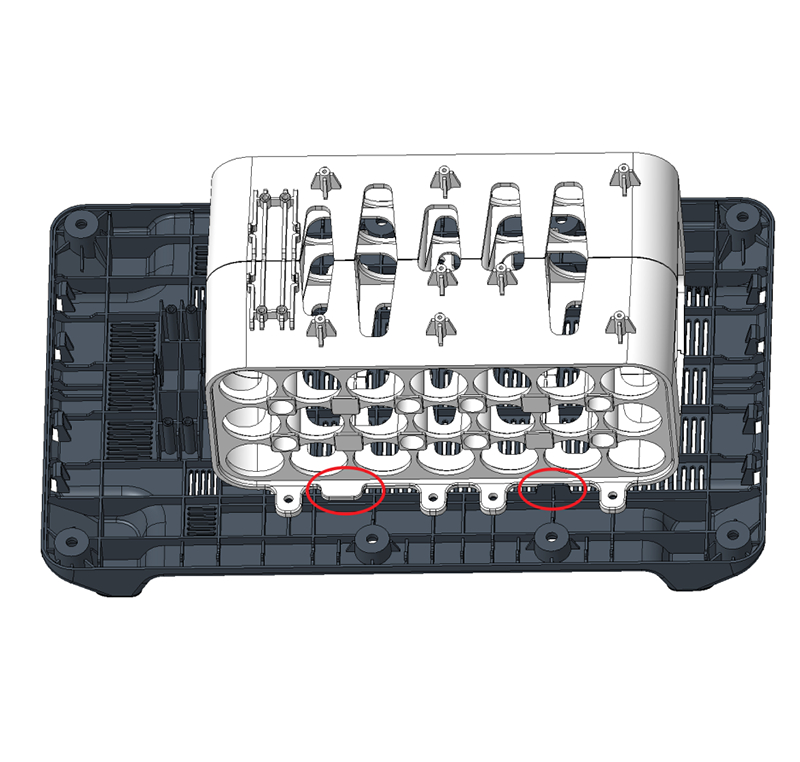

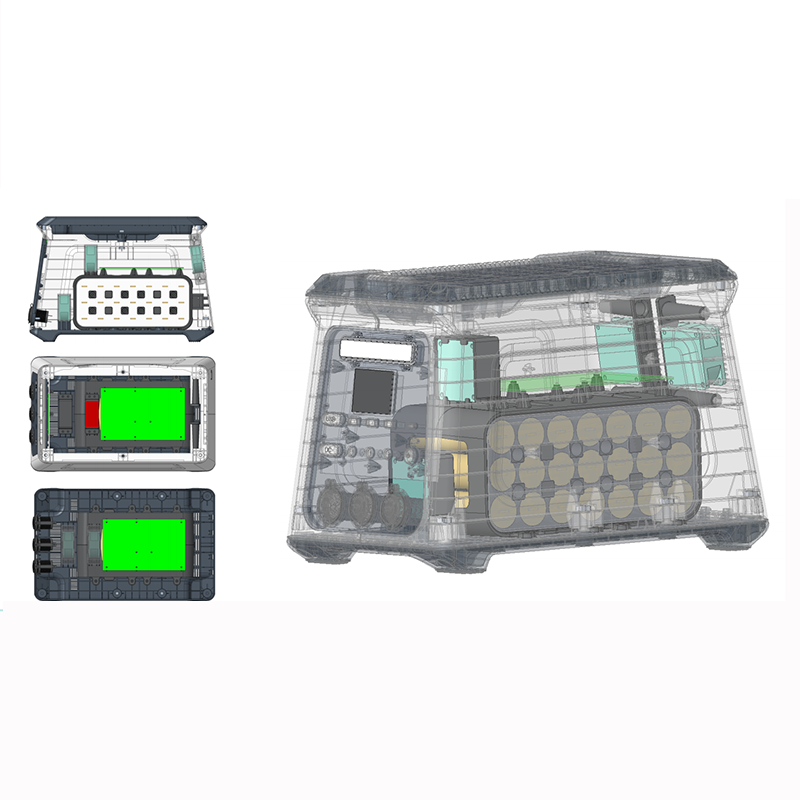

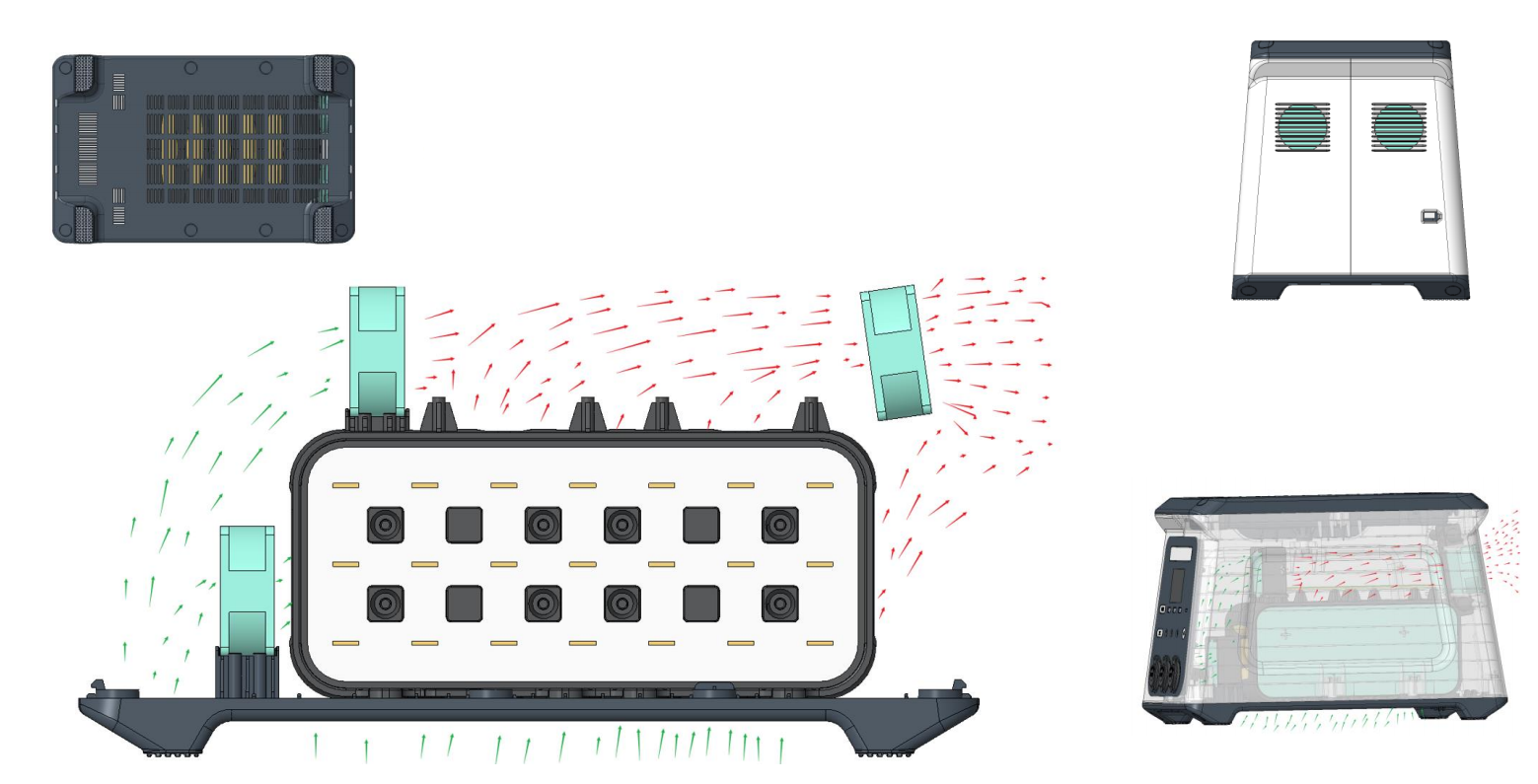

The phase is where the beautiful exterior is engineered for the real world. The digital model was meticulously designed in CAD software with internal ribs, screw bosses, and compartments for the battery, inverter, and cooling system. Material was specified as PC-ABS for its impact strength.

However, digital analysis alone is not enough. To physically verify the design, a series of "works-like" and "works-like/looks-like" prototypes were built. These functional prototypes were manufactured using processes like SLS (Selective Laser Sintering) for the plastic shell and CNC machining for the aluminum components, then assembled with real electronics.

A structural engineer conducts a drop test on a fully functional prototype, with high-speed cameras and data sensors recording the impact to validate the FEA simulations.

These prototypes were subjected to a battery of tests that mirrored the digital simulations:

Drop Tests: Units were dropped from specified heights onto concrete to validate the impact resistance of the corners and the integrity of the internal mounts.

Thermal Testing: The prototypes were run at full load to measure real-world temperatures and confirm the effectiveness of the cooling system and heat dissipation through the aluminum panels.

IP54 Ingress Protection Testing: The prototypes were used to validate the design of the silicone gaskets and the sealing interface between the two housing halves, ensuring no dust or water could penetrate.

The data gathered from these physical tests was irreplaceable. It led to design iterations such as thickening a critical rib near the battery mount and adjusting the tolerance on the port cover gasket. This process of "test-fail-redesign-retest" on functional prototypes ensured that the final injection-molded production units would perform flawlessly, safely, and reliably from the very first batch.

Conclusion: The Prototype as the Bridge to Perfection

The design of the Atlas power station underscores a critical truth in modern product development: physical prototypes are not a luxury but a necessity. By strategically employing prototype at each stage of the process—from foam models to validate ergonomics, to high-fidelity models to confirm aesthetics, to fully functional prototypes to prove structural integrity—the team created a continuous feedback loop between the digital and physical worlds.

This integrated approach prevented costly mistakes, fostered collaboration between industrial and engineering teams, and ultimately resulted in a product that is not only visually striking but also exceptionally durable and user-friendly. The Atlas stands as a testament to a design philosophy where every curve, rib, and material choice is informed by tangible evidence, ensuring the final product excels in the hands of the user and in the harsh conditions of the great outdoors.