low volume production

-

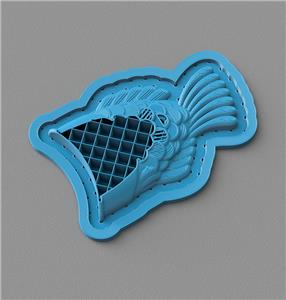

customized vacuum forming low volume production for outdoor parts

1. Exceptionally Low Tooling & Startup Costs Compared to other molding processes like injection molding, vacuum forming uses simple, single-sided molds. These molds can be crafted from inexpensive materials like wood, high-density urethane (HDU), or 3D-printed plastic, drastically reducing initial investment and making it ideal for prototyping and short production runs. 2. Rapid Prototyping and Short Lead Times The simplicity of the process allows for incredibly fast transition from design concept to tangible part. Molds can be produced and modified quickly, enabling rapid iteration, design validation, and faster time-to-market for new products. 3. Unmatched Capacity for Large Parts Vacuum forming is one of the most economical methods for producing very large plastic components. It is capable of creating massive parts—such as vehicle body panels, bathtubs, kayaks, and industrial machine covers—that would be prohibitively expensive or technically challenging to manufacture with other processes. 4. Superior Material and Finish Flexibility Manufacturers can choose from a vast library of thermoplastic sheets available in an extensive range of colors, textures, thicknesses, and material properties (e.g., ABS for strength, PETG for clarity, HIPS for cost-effectiveness). Parts can be formed with integrated finishes like gloss, matte, texture, or metallic, often eliminating the need for post-processing painting. 5. Cost-Efficiency for Low to Medium Volume Production For production batches ranging from a few dozen to several thousand units, vacuum forming offers an outstanding per-part cost advantage. The low maintenance of the molds and the efficient use of material make it the most economical choice for these volumes. 6. Durability and Structural Integrity Vacuum-formed parts are typically single-piece constructions with no welded seams, resulting in high strength and excellent impact resistance. This makes them perfect for applications requiring robust and reliable packaging, protective covers, or durable exterior components. In summary, the key highlights of vacuum forming are its low cost, speed for large parts, and exceptional flexibility, making it the premier choice for prototypes, large-scale components, and short- to medium-run production.

Email Details