customized vacuum forming low volume production for outdoor parts

1. Exceptionally Low Tooling & Startup Costs

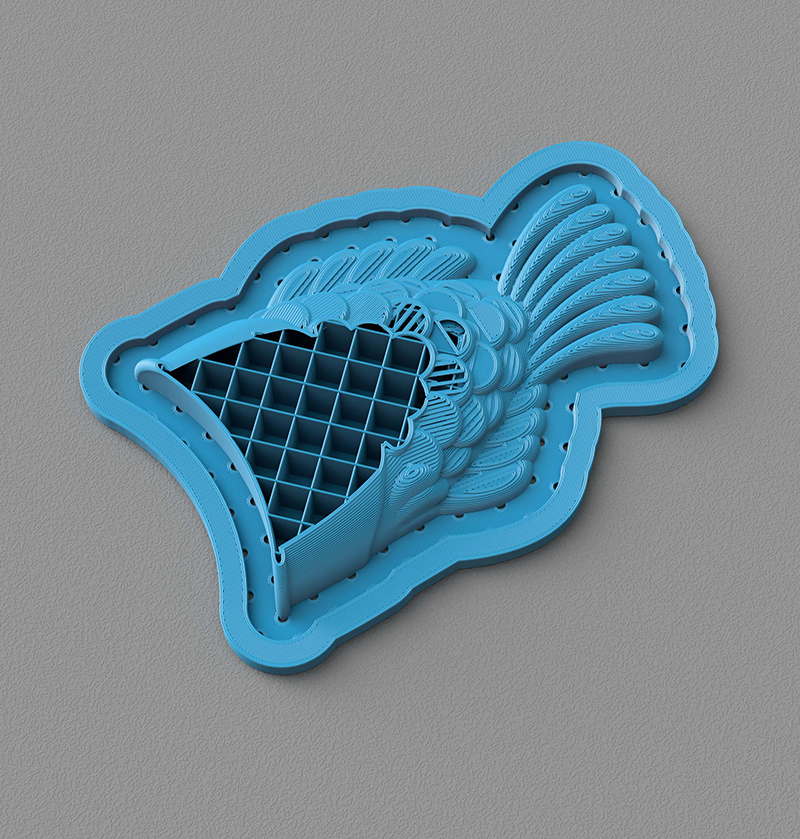

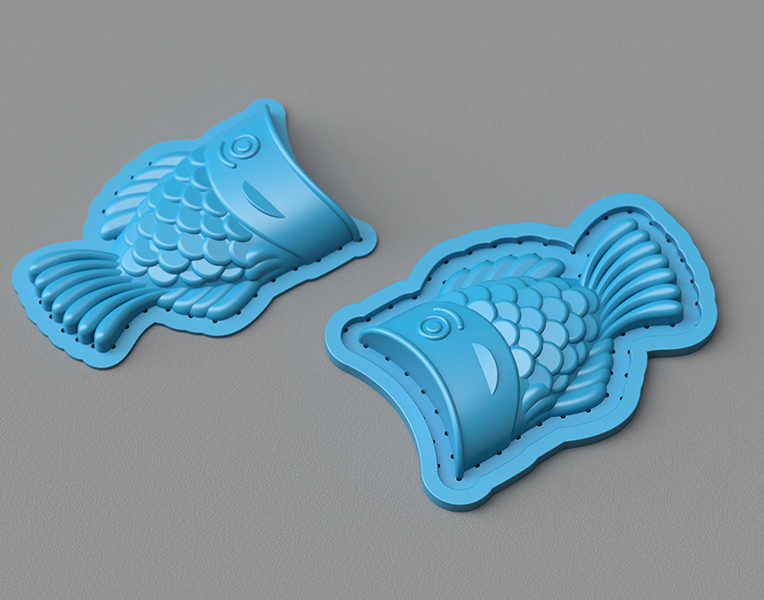

Compared to other molding processes like injection molding, vacuum forming uses simple, single-sided molds. These molds can be crafted from inexpensive materials like wood, high-density urethane (HDU), or 3D-printed plastic, drastically reducing initial investment and making it ideal for prototyping and short production runs.

2. Rapid Prototyping and Short Lead Times

The simplicity of the process allows for incredibly fast transition from design concept to tangible part. Molds can be produced and modified quickly, enabling rapid iteration, design validation, and faster time-to-market for new products.

3. Unmatched Capacity for Large Parts

Vacuum forming is one of the most economical methods for producing very large plastic components. It is capable of creating massive parts—such as vehicle body panels, bathtubs, kayaks, and industrial machine covers—that would be prohibitively expensive or technically challenging to manufacture with other processes.

4. Superior Material and Finish Flexibility

Manufacturers can choose from a vast library of thermoplastic sheets available in an extensive range of colors, textures, thicknesses, and material properties (e.g., ABS for strength, PETG for clarity, HIPS for cost-effectiveness). Parts can be formed with integrated finishes like gloss, matte, texture, or metallic, often eliminating the need for post-processing painting.

5. Cost-Efficiency for Low to Medium Volume Production

For production batches ranging from a few dozen to several thousand units, vacuum forming offers an outstanding per-part cost advantage. The low maintenance of the molds and the efficient use of material make it the most economical choice for these volumes.

6. Durability and Structural Integrity

Vacuum-formed parts are typically single-piece constructions with no welded seams, resulting in high strength and excellent impact resistance. This makes them perfect for applications requiring robust and reliable packaging, protective covers, or durable exterior components.

In summary, the key highlights of vacuum forming are its low cost, speed for large parts, and exceptional flexibility, making it the premier choice for prototypes, large-scale components, and short- to medium-run production.

| Material | ABS, HDPE,PP, PC, PETG, PET, etc | Model No | SMG-OEM-0004 |

| Color | Dark green | Style | OEM |

| Origin | China | Package | customized |

| Size | OEM | Logo | customized |

Part 1: Engineered for the Wild: Unbreakable Protection for Your Adventures

When you're miles deep in the backcountry or navigating choppy waters, your gear needs protection that matches your spirit of adventure. Our vacuum-formed utility cases are built to be the ultimate guardians of your essential equipment. Unlike standard storage solutions, these cases are crafted through advanced vacuum-forming technology that creates a seamless, monolithic structure without weak points. The result? A lightweight yet incredibly durable case that shrugs off impacts, resists moisture, and stands up to the harshest environments—from desert dust storms to alpine blizzards. Whether you're protecting drones for aerial photography, sensitive navigation devices for backcountry expeditions, or medical supplies for emergency scenarios, this case ensures your gear functions flawlessly when it matters most. The textured, non-slip surface provides secure handling even with gloved hands, while the reinforced corners add extra protection against drops and rough transport. For adventurers who demand reliability, this case isn’t an accessory—it’s a necessity.

Part 2: Built Tough: Technical Specifications for Outdoor Performance

Designed with input from survival instructors, expedition leaders, and outdoor photographers, every detail of this case is optimized for field use. The vacuum-forming process allows precise control over material distribution, ensuring consistent wall thickness and rugged durability without unnecessary weight. The case features a IP67-rated waterproof seal, certified to protect contents even when fully submerged. Add in UV resistance to prevent sun degradation and a operating temperature range of -40°F to 220°F (-40°C to 104°C), and you have a case ready for any adventure on the planet.

Technical Specifications Table:

| Feature | Specification | Outdoor Benefit |

|---|---|---|

| Material | High-Density Polyethylene (HDPE) Composite | Resists impacts, chemicals, and corrosion while remaining lightweight for backcountry travel |

| Waterproof Rating | IP67 Certified | Protects gear during river crossings, monsoons, or accidental submersion |

| Temperature Range | -40°F to 220°F (-40°C to 104°C) | Performs in arctic cold or desert heat without becoming brittle or deforming |

| Latches | Four Double-Throw Slam Latches | Easy operation with gloves, secure closure in high-wind conditions |

| Pressure Equalization | Automatic Gore-Tex® Valve | Prevents vacuum lock during altitude changes (ideal for mountain ascents/descents) |

| Hinge System | Continuous Stainless Steel Piano Hinge | No weak points, resistant to corrosion from saltwater or humidity |

| Interior | Customizable Pick-and-Pluck Foam | Create perfect compartments for any gear configuration; foam is waterproof and anti-microbial |

| Carry Options | Molded Handle + Removable Shoulder Strap | Comfortable carrying during long approaches or when wearing tactical gear |

| Dimensions | 20" x 14" x 8" (50x35x20 cm) | Fits standard expedition packs and vehicle storage systems |

| Weight | 4.2 lbs (1.9 kg) | Light enough for multi-day hikes, strong enough for checked airline baggage |

Part 3: Ready for Anything: Your Essential Outdoor Companion

This case transforms how you approach gear protection in the wild. Imagine securing your photography equipment during a kayaking trip through rapids, knowing your cameras will be dry and functional when you reach that perfect sunset spot. Picture your communication devices remaining operational during a sandstorm in the desert, or your medical supplies staying sterile and accessible during a mountain rescue operation. The case's stackable design allows efficient storage in vehicles and base camps, while the built-in tie-down points secure it to ATVs, boats, or pack animals. For overlanders, it organizes recovery gear and prevents tools from rattling loose on rough terrain. For photographers, it provides instant access to lenses and drones while protecting them from humidity and impacts. For survivalists, it keeps fire-starting materials dry and emergency rations protected from animals and the elements.

The case comes with our lifetime warranty against manufacturing defects—a testament to our confidence in its performance. We include a free set of replacement foam inserts so you can reconfigure the interior as your gear evolves. Join thousands of outdoor professionals and enthusiasts who trust this case to protect their most valuable equipment in the world's most challenging environments. Wherever your adventure takes you, take confidence with you.

Order today and receive our curated guide to "Field Gear Protection & Organization" plus early access to new accessory launches.