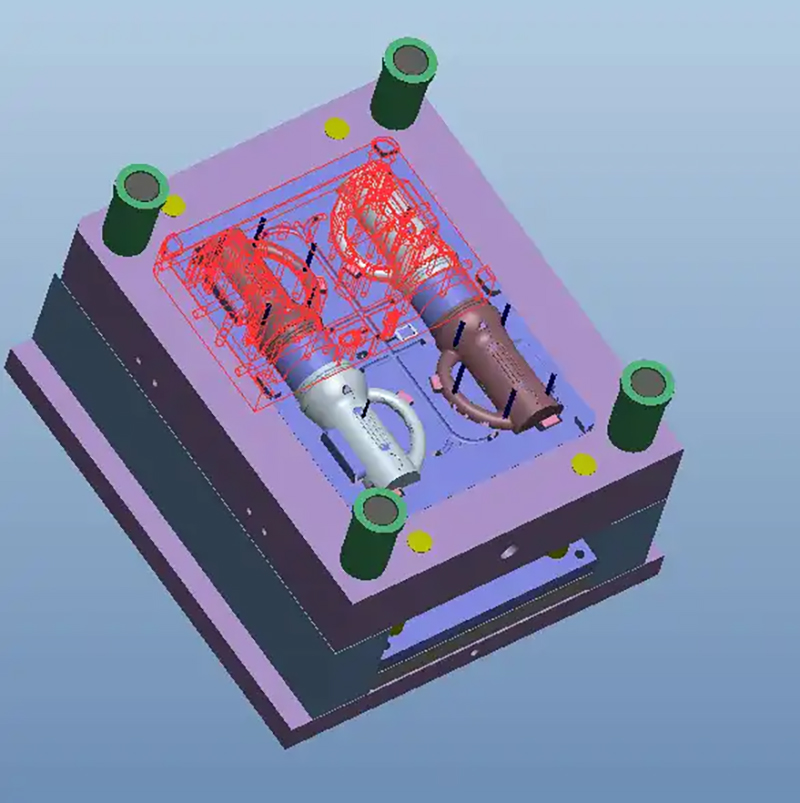

Chinese Outdoor Kettle Injection Mold

1.Unparalleled Durability: Crafted from premium hardened steel for exceptional longevity and resistance to wear, ensuring a massive production lifespan.

2.High-Precision Manufacturing: Enables the production of kettles with ultra-tight tolerances, guaranteeing perfect thread engagement and a leak-proof spout.

3.Innovative, User-Centric Design: Facilitates the creation of ergonomic kettles with secure handles and anti-slip textures.

| Material | PP, PE, Tritan, TPU | Model No | SMG-M-0006 |

| Color | Customized | Style | OEM |

| Origin | China | Package | customized |

| Size | OEM | Logo | customized |

Crafting the Wild: Your Premier OEM Partner for High-Performance Outdoor Kettle Molds

1. Introduction: Where Adventure Meets Precision Engineering

For the modern adventurer, a kettle is more than just a container; it's a vital piece of gear for hydration, cooking, and survival. It must be tough, lightweight, reliable, and ergonomic. At Samgo, we understand this profoundly. We don't just manufacture molds; we engineer the very foundation of your next best-selling outdoor kettle. We are a specialized OEM partner, dedicated to transforming your innovative designs into high-precision, durable, and mass-producible realities that are built for the wild.

2. Product Overview: The Anatomy of an Unbeatable Outdoor Kettle Mold

Our outdoor kettle mold series is the culmination of advanced engineering, material science, and a deep understanding of outdoor needs. It is designed to produce kettles that stand up to extreme conditions, from the freezing altitudes of mountaineering to the rugged trails of backpacking.

Core Philosophy: Durability, Functionality, and Efficiency.

Target Products: Lightweight trekking kettles, versatile camping kettles with integrated lids, and durable, wide-base kettles for stable heating over a campfire.

3. Key Product Highlights & Outdoor Advantages

Highlight 1: Extreme Environment Durability

Mold Core: Manufactured from premium H13 Hot-Work Steel (or Stavax ESR for supreme finish), hardened to HRC 48-52. This ensures exceptional resistance to wear, corrosion, and thermal fatigue.

Outdoor Advantage: Produces kettles with uniform wall thickness and structural integrity, preventing cracks or failures under physical impact or rapid temperature changes.

Highlight 2: Ultra-Precision for Leak-Proof Performance

Technology: CNC machining and EDM achieve mirror-level finishes and tolerances within ±0.05mm.

Outdoor Advantage: Guarantees perfect screw threads for a 100% leak-proof seal and seamless spout integration, keeping contents safe in a bouncing backpack.

Highlight 3: Ergonomic & Versatile Design Flexibility

Modular Design: Our mold architecture allows for interchangeable components. We can easily integrate features for foldable handles, integrated lids with locks, and multi-material over-molding.

Outdoor Advantage: Enables user-centric designs that outdoor enthusiasts demand: easy to carry, secure to use, and space-saving.

Highlight 4: Optimized for High-Efficiency Production

Systems: Standard high-performance hot runner systems and advanced conformal cooling channels.

OEM Advantage: Reduces cycle time, minimizes material waste and part warpage, allowing you to scale production rapidly and cost-effectively.

4. Our Comprehensive OEM Services: Beyond the Mold

Phase 1: Co-Design & Engineering Consultation

DFM (Design for Manufacturability) Analysis.

Material Selection Guidance for food-grade, BPA-free, heat-resistant polymers.

Phase 2: Prototyping & Validation

Rapid Prototyping (3D printing, CNC) for functional testing.

Digital Mold Flow Analysis to predict and prevent manufacturing defects.

Phase 3: Precision Manufacturing & QC

Full Process Documentation for traceability.

In-process Inspection using CMM (Coordinate Measuring Machine) and high-precision tools.

Phase 4: Post-Sales & Lifelong Support

Comprehensive Maintenance Training for your production team.

Lifelong Technical Support & Guaranteed Spare Parts Supply.

5. Technical Specifications Table

| Category | Specification | Description & Benefit |

|---|---|---|

| Mold Base Material | 1050/718 Pre-hardened Steel (Standard) | Robust and stable foundation for mold core and cavity. |

| Mold Core/Cavity Material | H13 Hot-Work Steel (Standard); Stavax ESR (Premium) | Standard: Excellent toughness. Premium: Superior polishability for a mirror-finish. |

| Hardness (HRC) | 48-52 | Ensures long-term durability and resistance to wear. |

| Tolerance | ±0.015mm ~ ±0.05mm | Guarantees consistent part dimensions and perfect sealing. |

| Surface Finish | SPI-SPE A-1 (Mirror Finish) / Texture available | Glossy surface or textured grip to hide scratches. |

| Runner System | Hot Runner (Standard) | Reduces waste, shortens cycle time, enables automation. |

| Lifespan (Shots) | 1,000,000+ | Maximizes ROI and ensures consistent quality over high volumes. |

| Ejection System | Ejector Pins, Sleeves, Stripper Plate | Smooth, damage-free ejection of complex kettle geometry. |

6. Material Guide for Outdoor Kettles

| Material | Key Characteristics | Ideal For | Our Mold Compatibility |

|---|---|---|---|

| Polypropylene (PP) | Lightweight, chemical resistance, cost-effective. | Budget-friendly, lightweight trekking kettles. | Excellent - easy flow, low stress. |

| Tritan™ Copolyester | Clarity, high impact strength, BPA-free, odor resistance. | Premium kettles where aesthetics and toughness are key. | Excellent - requires good polish and cooling. |

| PPSU (Polyphenylsulfone) | Medical-grade, extreme heat resistance, high strength. | Mountaineering kettles for direct flame heating. | Excellent - requires high molding temperatures. |

| Food-Grade SAN | Crystal clarity and rigidity. | See-through kettles for visual liquid level check. | Good. |

7. Why Partner With Us?

Deep OEM Expertise: We are structured to be a seamless extension of your team.

Proven Track Record: We have successfully delivered molds for leading brands in the outdoor gear industry.

A Partnership for the Long Trail: We are committed to your success from concept to mass production.

8. Let's Engineer Your Legacy

Ready to bring your next-generation outdoor kettle to life? Contact our OEM project specialists today for a free, no-obligation project consultation and quotation.