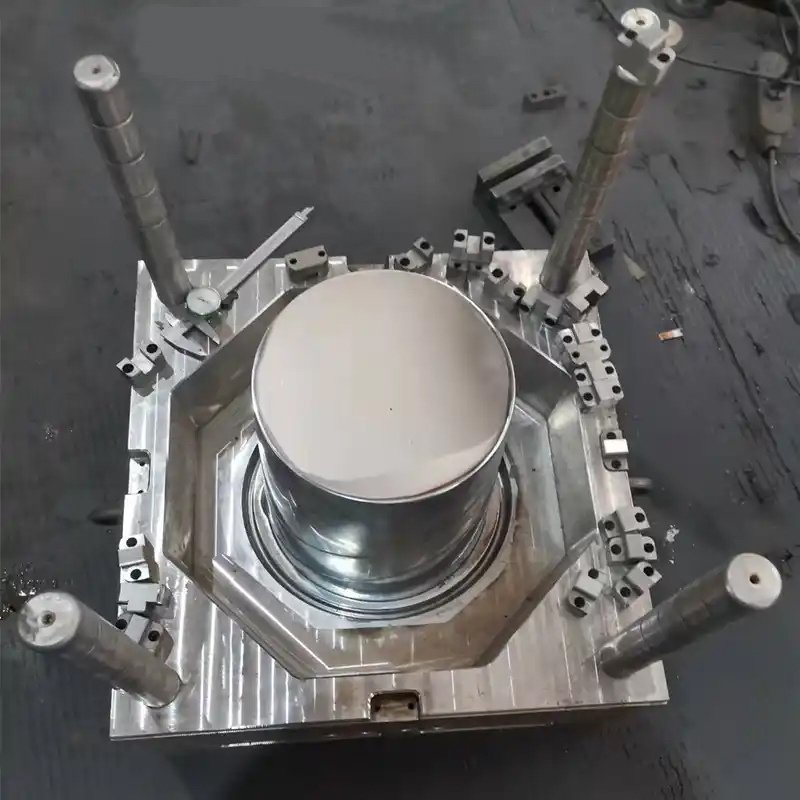

OEM plastic bucket mold

- China

1.Long Service Life (Made from hardened tool steel)

2.Excellent Product Finish (Smooth, high-gloss bucket surface)

3.High Production Efficiency (Fast cycle times)

4.Stable & Reliable Performance (Durable construction)

5.Easy Demolding (Prevents part sticking and damage)

6.Corrosion-Resistant (For extended mold life)

7.Low Maintenance (Designed for continuous operation)

| Material | PP, HDPE,etc | Model No | SMG-M-0005 |

| Color | Customized | Style | OEM |

| Origin | China | Package | customized |

| Size | OEM | Logo | customized |

Professional Injection Molds for Outdoor Water Buckets: Your Partner in Durable Hydration Solutions

Engineered for the Great Outdoors

Welcome to our world of precision engineering, where we transform the simple water bucket into a reliable companion for outdoor adventures, camping trips, emergency preparedness, and agricultural use. Our specialized injection molds are not just tools for manufacturing; they are the foundational blueprint for creating water buckets that embody durability, functionality, and user-centric design. We combine state-of-the-art mold manufacturing with a deeply collaborative OEM approach to bring your unique vision for outdoor gear to life, ensuring your products stand up to the elements and stand out in the marketplace.

Unparalleled Product Advantages - Molds Built for Rugged Performance

Our molds are engineered with a singular focus: to produce outdoor water buckets that excel in real-world conditions. Every design decision is made with the end-user's outdoor experience in mind.

1.1 Superior Material & Structural Integrity

Reinforced Base & Handling Points: Our mold designs incorporate features for thicker walls at the base and critical stress points (like handle attachments and spout openings). This prevents cracking and deformation, whether the bucket is filled with ice, dropped on rough terrain, or subjected to heavy loads.

Premium Mold Steels: We utilize hardened steels like H13 for cores and cavities and often incorporate Stainless Steel (SS420, 440C) for critical components. This provides exceptional resistance to abrasion from filled materials and corrosion from water or cleaning agents, ensuring a long mold life and consistent part quality over millions of cycles.

1.2 Advanced Surface Finish Technology

A bucket's surface is its first line of defense. Our molds are polished and textured to the highest standards.

Mirror Polishing: For a smooth, easy-to-clean interior that resists staining and bacterial growth.

Custom Textures (e.g., EDM, Laser Etching): We can impart non-slip grips on the sides, a rugged, scratch-hiding "armor" pattern on the base, or even your branded logo directly onto the bucket. Textured surfaces also help to conceal minor scuffs and scratches acquired during outdoor use.

1.3 High-Efficiency, Precision Molding

Hot Runner Systems: Standard in our designs, hot runner systems eliminate sprue waste, reduce cycle times, and ensure consistent material flow. This results in lower per-part costs and superior, cosmetically perfect buckets.

Optimized Cooling Channels: Through Moldflow analysis, we design conformal cooling channels that follow the contour of the bucket. This ensures uniform cooling, drastically reduces cycle times, and minimizes part warpage and internal stresses, leading to a dimensionally stable and stronger final product.

Highlighting Key Outdoor Features - From Mold to Mountain

The features we build into our molds directly translate into the benefits your customers will value.

Table 1: Mold Feature to Outdoor Benefit Translation

| Mold Feature | Resulting Product Feature | Benefit for the Outdoor User |

|---|---|---|

| Multi-Cavity & Family Mold Design | Ability to produce the main bucket and attached components (e.g., lid, measuring cup) simultaneously. | Integrated, convenient storage system; no lost parts. |

| Collapsible/Stacking Part Design | Buckets that nest or collapse for compact storage. | Saves crucial space in backpacks, vehicles, and emergency kits. |

| Undercut Mechanisms (Sliders/Lifters) | Integrated pour spouts, leak-proof gasket grooves, and robust handle attachment points. | Controlled pouring, no leaks during transport, secure and comfortable carrying. |

| Textured Cavity Surfaces | Molded-in graduations (liters/gallons), non-slip grips, and brand logos. | Easy measurement of water/feed, secure handling in wet conditions, and strong brand presence. |

| High-Flow, High-Impact Material Gating | Ability to use tough, outdoor-grade plastics like PP, HDPE, or TPU. | Excellent impact resistance in cold weather, durability against UV radiation, and overall longevity. |

Our Comprehensive OEM/ODM Service - Your Vision, Our Execution

We are more than a mold maker; we are your strategic manufacturing partner. Our flexible OEM and ODM services are designed to provide a seamless journey from your initial concept to a market-ready product.

3.1 Collaborative Design & Engineering Support (DFM)

Before any metal is cut, our engineering team works closely with you. We provide a comprehensive Design for Manufacturability (DFM) report that analyzes your product design, suggesting optimizations for cost, performance, and manufacturability. We help you select the right plastic material for your target market and application.

3.2 End-to-End Project Management

You will be assigned a dedicated project manager who serves as your single point of contact. We ensure transparent communication through regular progress reports, including photos and videos of the mold-making stages (machining, heat treatment, polishing, assembly) and sample approvals.

3.3 Strict Quality Control Protocol

Quality is ingrained in our process. We adhere to a rigorous multi-stage inspection protocol.

Table 2: Our Quality Control Process

| Stage | Inspection Method | Key Focus Areas |

|---|---|---|

| 1. Raw Material | Material Certificates | Verifying grade and properties of steel and pre-hardened components. |

| 2. Machining | CMM (Coordinate Measuring Machine) | Ensuring core/cavity dimensions, slide fits, and ejector pin locations are within microns of the CAD model. |

| 3. T1 Sample | Dimensional & Visual Inspection | First article inspection. Checking part weight, wall thickness, critical dimensions, and surface appearance. |

| 4. Mold Testing | Injection Molding Trial | Testing the mold under production conditions. Verifying cycle time, demolding ease, and part performance (e.g., leak test). |

| 5. Pre-Shipment | Final Assembly Check & Sample Approval | Comprehensive check of the complete mold. Shipping T2 samples to you for final approval before delivery. |

3.4 Logistics & After-Sales Support

We handle all export formalities and can ship globally. Our support continues after delivery with comprehensive technical documentation (mold manual, maintenance schedule) and readily available spare parts to minimize your downtime.

Technical Specifications & Customization Options

Table 3: Technical Specifications Overview

| Parameter | Specifications & Options |

|---|---|

| Mold Base Steel | LKM Standard (45# Steel), P20 (Pre-Hardened) |

| Core & Cavity Steel | H13 (Hot Work Steel), SS420 (Stainless Steel), S136 (Mirror Polish Steel) |

| Hardening & Treatment | Vacuum Heat Treatment (HRC 48-52), Nitriding, Chrome Plating |

| Surface Finish | Mirror Polish (SPI A1), Textured (VDI 18-40), EDM Finish |

| Runner System | Hot Runner (Preferred) for efficiency, or Cold Runner as required. |

| Ejection System | Ejector Pins, Sleeves, Stripper Plate, Air Poppet Valves. |

| Lifespan | 1,000,000+ cycles (Standard), up to 2,000,000+ cycles with premium steel and construction. |

| Compatible Plastics | Polypropylene (PP), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), TPU. |

| Lead Time | Typically 45-60 days, depending on complexity and current project load. |

Customization We Offer:

Capacity: From 2-gallon camping buckets to 5-gallon+ heavy-duty utility buckets.

Color: Single material color or multi-color combinations using specialized molding techniques.

Features: Molded-in handles (fixed or swing), spouts, lids (screw-on, snap-fit), gasket grooves, and custom measurement markings.

Branding: Deeply molded logos, tags, or instructional text for a permanent, professional brand identity.

Why Choose Us as Your Outdoor Bucket Mold Partner?

Deep Outdoor Industry Insight: We understand the specific demands placed on gear used in camping, farming, and emergency scenarios. We engineer resilience into every mold.

Proven OEM Expertise: We have a successful track record of partnering with brands, from startups to established companies, to develop best-in-class products.

Technological Leadership: Our investment in advanced machinery (CNC, EDM, CMM) and engineering software (CAD/CAM/CAE) guarantees precision, efficiency, and reliability.

Total Cost-Effectiveness: By optimizing the mold design for speed and material usage, we ensure your long-term production costs are minimized, maximizing your ROI.

Let's Build Your Perfect Outdoor Bucket

The journey to creating a superior outdoor water bucket starts with a perfect mold. Contact our OEM project specialists today for a free, no-obligation consultation and quotation. Share your ideas, sketches, or samples, and let us show you how we can turn them into a high-performance, market-leading product.

Get in touch to receive your personalized DFM analysis and project proposal.