Chinese manufacturer high quality injection molds for outdoor parts

1.Unmatched Durability for Harsh Environments

Engineered for Impact Resistance: Manufactured from high-grade, UV-stabilized polymers to withstand brutal impacts, drops, and abrasion from rock, ice, and trail debris.

2.Weatherproof & Corrosion-Resistant: Superior material formulation ensures complete resistance to moisture, salt spray, extreme temperature swings, and UV radiation, preventing fading, brittleness, and corrosion.

3. Lightweight & Ergonomic Design for Peak Performance

Precision-Engineered Lightweighting: Advanced mold flow analysis allows for complex geometries that maximize strength while minimizing weight, reducing fatigue on long treks and climbs.

All-Terrain Grip & Handling: Textured, over-molded surfaces provide a secure, non-slip grip even with wet hands or gloves, ensuring total control in rain, snow, or mud.

4. Superior Structural Integrity & Reliability

Seamless, Monolithic Construction: Injection molding creates a single, unified part with no weak seams or joints, guaranteeing exceptional structural integrity under load and stress.

Rigorous Quality Assurance: Every component is tested to perform flawlessly across an extreme temperature range (-40°F to 220°F / -40°C to 104°C), ensuring reliability from desert to alpine environments.

| Material | ABS with UV, HDPE, PC, ASA,etc | Model No | SMG-OEM-0005 |

| Color | Customized | Style | OEM |

| Origin | China | Package | customized |

| Size | OEM | Logo | customized |

Part 1: Forge Your Legacy in the Wild: Outdoor parts Injection Mold

Welcome to the forge where legendary outdoor gear is born. Every piece of equipment that accompanies an adventurer into the untamed wild carries a story—a story of resilience, precision, and unwavering reliability. The Apex Series High-Performance Injection Mold isn't just a tool; it's the silent architect behind those stories. Engineered for outfitters, survivalists, and pioneering outdoor brands, this mold embodies the spirit of exploration. It transforms raw, potent polymers into critical components that must perform under the harshest conditions imaginable: from the salt-spray of ocean kayaking to the sub-zero temperatures of alpine ascents, and the abrasive sands of desert trekking. We didn't just design a mold; we engineered a bedrock for innovation. By choosing the Apex Series, you're not merely manufacturing a product; you're crafting a trusted companion for the world's most demanding environments. This commitment to excellence ensures that every buckle, every housing, every latch, and every specialized component produced has the endurance of a mountain and the precision of a master navigator, ready to empower the next generation of outdoor heroes.

Our philosophy is rooted in a deep understanding of the outdoor ecosystem. We know that a failed component isn't just an inconvenience; it can compromise safety and mission success miles away from civilization. Therefore, the Apex Mold is built with a core-to-cavity integrity that mirrors the ruggedness of the gear it creates. It's crafted from premium P20 and H13 tool steels, hardened and tempered to resist wear far beyond industry standards, ensuring a lifecycle that spans hundreds of thousands of cycles without degradation in part quality. The mold's internal cooling channels are optimized using state-of-the-art simulation software, drastically reducing cycle times and ensuring consistent crystallinity and material strength in every shot—whether you're molding with glass-filled nylons for extreme stiffness or weather-resistant TPUs for critical flexibility. This isn't mass production; it's mission-specific production. Every component that emerges is a testament to durability, a perfect blend of molecular integrity and functional design, ready to bear loads, resist impacts, and endure UV radiation without failing. This is the promise of the Apex Series: to provide the foundational building blocks for gear that doesn't just exist in the wild but thrives in it.

Key Outdoor Applications Include:

Climbing & Mountaineering: Carabiner bodies, belay device components, harness buckles, ice axe grips.

Water Sports: Kayak hatch latches, waterproof case hinges, paddle ferrule connectors, dive instrument housings.

Camping & Survival: Tent pole connectors, stove control valves, multi-tool components, heavy-duty zipper pulls.

Hunting & Fishing: Reel components, ammunition casings, blind fasteners, scent-proof container lids.

Backpacking: Load-bearing buckle systems, trekking pole locks, hydration pack valves, quick-release mechanisms.

Part 2: Engineering Precision Meets Unyielding Durability: A Technical Deep Dive

The Apex Series Injection Mold is where computational engineering meets the raw challenge of nature. Every specification has been meticulously chosen to address the unique demands of outdoor manufacturing, ensuring that your production process is as reliable as the final product in the field.

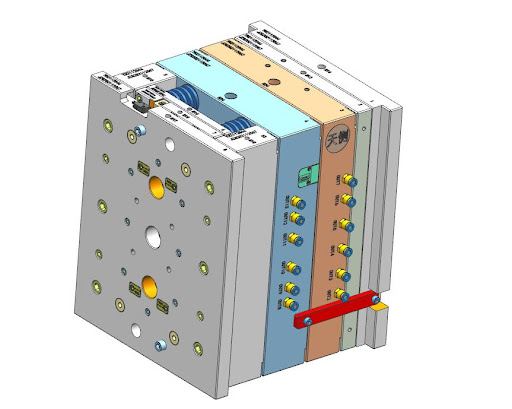

| Feature | Specification | Benefit for Outdoor Gear |

|---|---|---|

| Core Material | Premium P20, 718, NAK80, H13, S136 Tool Steel (HRC 48-52) | Superior hardness and exceptional resistance to abrasive filled polymers (e.g., glass-filled nylon), ensuring longevity and perfect finish over a massive production run. |

| Surface Treatment | Advanced Nitriding & Polishing (Mirror Finish Option) | Creates an ultra-hard, low-friction surface that minimizes part sticking, reduces wear, and allows for the flawless surface finish required for consumer-grade gear. |

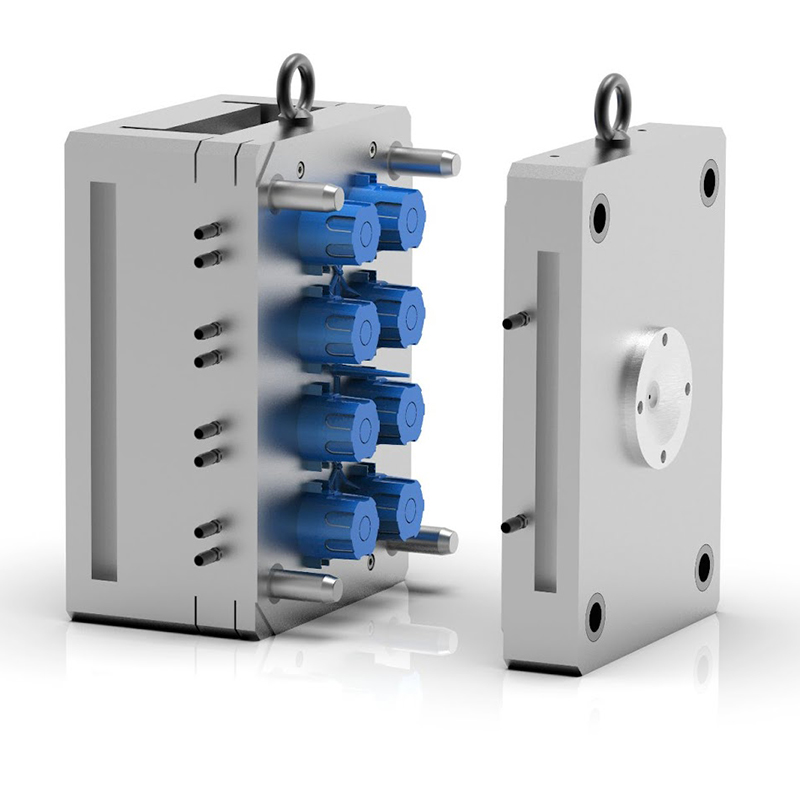

| Cooling System | Conformal Cooling Channels | Drastically reduces cycle time and ensures uniform cooling. This eliminates internal stresses and warping, critical for parts requiring dimensional stability under load. |

| Ejection System | Stainless Steel Ejector Pins & Sleeves | Corrosion-resistant and robust, providing reliable, jam-free ejection every cycle to maintain high production uptime and perfect part integrity. |

| Tolerance Rating | ±0.05mm | Unmatched precision for producing interlocking parts, airtight seals, and complex mechanisms that are hallmarks of high-end outdoor equipment. |

| Runner System | Hot Runner System (Optional) or Cold runner | Elimates material waste (sprue and runners), reduces cycle time, and allows for fully automated production, ideal for sustainable and cost-effective manufacturing. |

| Venting | Micro-machined Venting Channels | Prevents gas traps and burning, which is crucial when using weather-resistant polymers that can off-gas, ensuring a defect-free, structurally sound part every time. |

| Corrosion Resistance | Chrome Plating & Specialized Coatings | Provides ultimate protection against the humidity and potential corrosive elements present in manufacturing environments, guaranteeing mold longevity. |

Beyond the table, the mold's architecture is designed for versatility. We offer multi-cavity designs to scale your production to demand, from prototyping batches to full-scale runs. The mold frames are massively overbuilt to withstand high injection pressures without any deflection, ensuring that parting lines remain perfectly sealed and flash-free—a non-negotiable quality for gear that must keep out moisture and dirt. Our engineering team specializes in designing complex actions, including sliders and lifters, which allow for the creation of sophisticated undercuts and internal features common in tactical and outdoor gear designs without the need for secondary operations. This means you can mold a complex, fully functional carabiner gate mechanism or a self-locking buckle in a single, efficient shot. Furthermore, the mold is fully compatible with engineering-grade polymers that define the outdoor industry, including Nylon 6/6 (PA66), Polycarbonate (PC), Acetal (POM), and various thermoplastic elastomers (TPE/TPU), providing the impact resistance, fatigue endurance, and environmental resistance that end-users depend on for their safety and performance.

Part 3: Your Partner from Prototype to Peak: The End-to-End Advantage

Choosing the Apex Series Injection Mold means investing in more than hardware; it's a partnership dedicated to elevating your brand and empowering your vision. We understand that bringing a new outdoor product to market is an expedition in itself, fraught with challenges and unknowns. Our process is designed to be your base camp, providing support, expertise, and flawless equipment from the initial concept to the final product on the retail shelf.

Our collaborative journey begins with your vision. Our design-for-manufacturability (DFM) analysis is legendary within the outdoor industry. We don't just take your CAD file and build a mold; we analyze it with the ruthless practicality of a seasoned guide. We will identify potential stress points, recommend draft angles for effortless ejection, suggest optimal wall thicknesses for strength-to-weight ratio, and advise on material selection based on the intended use-case—be it extreme UV resistance for desert gear or impact resistance for climbing hardware. This proactive approach prevents costly redesigns and ensures your product is not only manufacturable but optimized for peak performance in the field. We then move to precision machining, utilizing 5-axis CNC and EDM processes to create mold cavities with microscopic accuracy. Every curve, every angle, every texture is machined to perfection, ensuring that the first article parts that come out of the mold are production-ready and embody the quality your brand represents.

Once the mold is commissioned and tested, our support continues. We provide comprehensive documentation, including a detailed maintenance guide to ensure your mold continues to perform like new after thousands of cycles. We offer readily available spare parts and a technical support hotline to minimize any potential downtime. The result is a seamless production flow that allows you to focus on what you do best: designing, marketing, and selling world-class outdoor gear. The reliability of the Apex Mold translates directly to your supply chain reliability, enabling you to meet market demand quickly and scale your operations with confidence. Ultimately, this partnership is about building a legacy. The components produced with this mold will be trusted by adventurers scaling remote peaks, navigating treacherous rivers, and sleeping under the stars in punishing weather. They will become an integral, albeit unseen, part of their experiences and successes. By investing in the Apex Series, you are making a commitment to those adventurers—a promise of quality, a guarantee of durability, and a testament to the spirit of exploration that drives us all. Let's build the future of outdoor gear, together.